If your hole tolerances are zero see below then advanced circuits will assume that you are ok with our default hole tolerance.

Pcb copper etching tolerance.

The minimum trace width space is 0 003.

Hdi or mft boards can be produced with smaller tolerances.

The standard thickness of a pcb is normally around 1 6mm.

Our default hole tolerance is listed above.

Ipc a 600 class 2 and on the basis of following technical specifications.

Normally tolerance will occur due to pcb processing steps such as electroless copper solder mask and other types of finish on the surface.

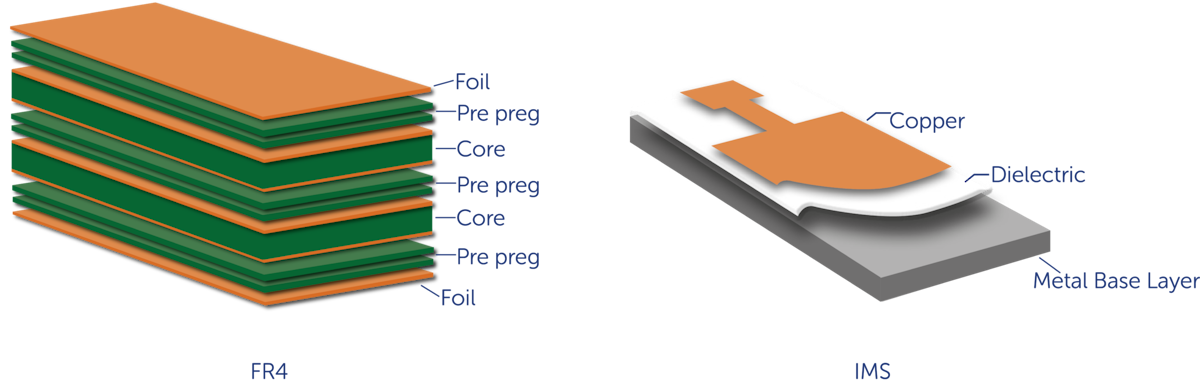

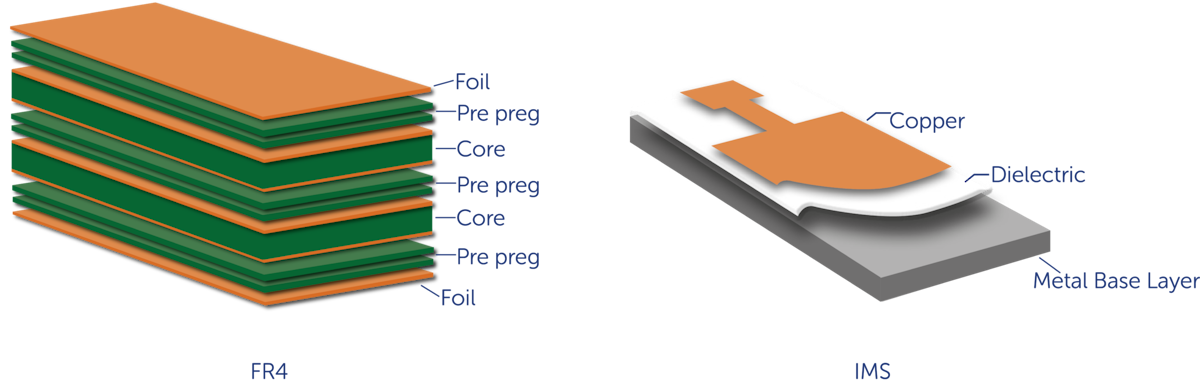

Pcb is an acronym that stands for printed circuit board that helps to connect active passive electronic components with pads tracks and lines incorporated on a laminated copper sheet.

Start copper or base copper the copper thickness as received from our suppliers.

The production of printed circuit boards is carried out according to the valid ipc guidelines and standards et al.

Board thickness tolerance t 1 0mm 0 1mm.

A premium is charged for trace width spacing less than 005.

Where possible design to printed circuit board manufacturing industry standard mid range tolerances.

However our standard tolerance for line width is 20 or 1 mil tighter tolerance can be achieved with special processing.

In order to facilitate in production we suggest you relax your minimum to be.

0 003 custom spec upon request 1 oz and 2 oz finished copper weight and 3 oz finished copper weight when starting with 2 oz foil only.

Trace width is the minimum width of a copper feature usually traces.

Relax pcb etching tolerance customer required controlling the tolerance of xxx for all traces.

When we consider the layer copper thickness on a pcb we refer to.

A number of stages are involved in proper pcb fabrications which include designing layout routing etching troubleshooting.

For a board of this thickness it is not unusual to have a thickness tolerance of 0 15mm.

If you use these tolerances you should be able to source your boards from any manufacturer in the world without cost penalty.

Board thickness tolerance t 1 0mm 10.

Place the pcb into the etching solution and agitate for 25 30 minutes or until all the copper has dissolved around the design if you would prefer not to agitate by hand here is another instructable i created on how to make a agitator using an old cd rom drive.

Copper spacing is the minimum air gap between any two adjacent copper features.

End copper or finished copper this is the final thickness of copper on the finished pcb.

The ipc 4562 and ipc a 600 define both the acceptable thickness and tolerances for both the base and.